Laser News

Fiber-Coupled Output LD

As a new type of light source, semiconductor laser (LD) has been one of the focuses of people because of its characteristics such as high conversion efficiency, small size, light weight, high reliability, direct modulation and strong ability to integrate with other semiconductor devices. . The fiber-coupled output high-power laser diode module has the characteristics of small size, good beam quality, and high brightness. It can replace the existing YAG solid-state lasers directly for laser beam guidance, medical treatment, laser processing, photoelectric detection, and lidar. However, semiconductor lasers have a large wavelength drift with temperature, which is required to be widely used. The problem of power driving and heat dissipation has always been that the driving power has a high current stability. To avoid damage to the laser due to overheating or excessive power consumption, it is required that the power supply is free from power-on and switch-on current shocks. The power part of the traditional current source circuit generally adopts a circuit form in which a power amplifier tube and a laser are connected in series. The advantage of this circuit form is that the circuit is simple, but in order to make the power amplifier tube have constant current characteristics, it must work in the amplification region, especially when the current source output current is required to have a large range of variation, a large Power consumption, generating excessive heat, will reduce power efficiency and reduce system reliability. Multi-die series-excitation fiber-coupled output semiconductor lasers can output very high continuous laser power. Since the efficiency of the laser is only 35% to 45%, for the continuous laser output of more than ten watts, in order to improve the efficiency of the semiconductor laser current source, it must be used It has high efficiency and low power consumption PWM type DC / DC conversion circuit as the drive current source of the laser, and solves the problem of DC / DC conversion circuit control and power-on shock. According to the application requirements of fiber-coupled lasers, this paper develops an LD module drive current source and temperature control circuit system.

Basic Principles of Fiber-Coupled Output LD

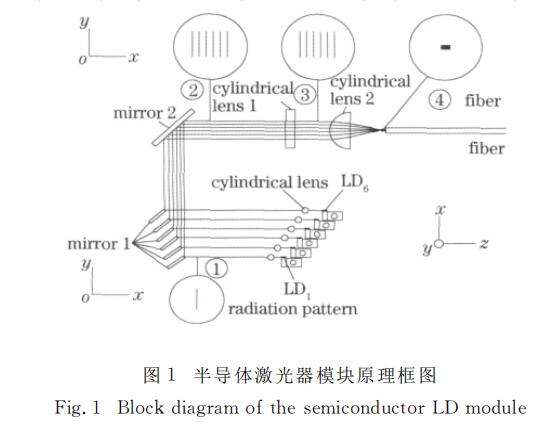

The principle block diagram of a multi-die series excitation fiber-coupled output semiconductor laser module is shown in Figure 1. LD1 to LD6 are laser diode units. The light beam emitted by the LD is first collimated by a micro-cylinder lens. The collimated light beam can be considered as a linear light source with a certain divergence angle in the y direction. The output beam of ~ LD6 is reflected twice by mirror 1 and mirror 2, respectively. The propagation direction of the beam is rotated 180 °, and a group of composite beams are formed. Into a set of parallel line light sources, each line light source has a certain divergence angle in the x and y directions (corresponding to the slow axis divergence angle of the laser diode and the fast axis divergence angle, respectively), using two vertical The placed cylindrical lens 1 and lens 2 can focus and couple such a composite beam into an optical fiber for power synthesis. The combined beams are shown as ③ and ④ in the figure. The main technical indicators of the laser drive current source are: 1) the output current is continuously adjustable from 0 to 4A; 2) the output voltage varies from 8 to 17V; 3) the relative stability of the output current of the current source is better than 0.5%; 4) none Current impact; 5) The operating temperature range of the LD module is -45 ℃ ~ 50 ℃; 6) In order to avoid the laser wavelength of the LD module from drifting too much with the temperature, the ambient temperature of the LD die is controlled between -5 ℃ and 20 ℃.